1. Introduction

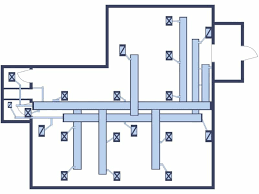

In large-scale projects, HVAC plant rooms are crucial for housing HVAC equipment and associated services.

These rooms form the operational core of heating, ventilation, and air conditioning systems. Proper design ensures that the HVAC plant room meets operational, maintenance, safety, and future expansion needs.

The HVAC design engineer plays a prime role in ensuring the design aligns with these objectives while coordinating with other disciplines such as structural, civil, health and safety, process, instrumentation, mechanical, and electrical teams.

2. Key Considerations for HVAC Plant Room Design

2.1 Future Expansion

Planning for future growth is a fundamental consideration when designing HVAC plant rooms. Early collaboration with the client is essential to assess potential future requirements. This includes:

- Allocating additional space to accommodate new equipment or upgrades.

- Designing modular systems that can be expanded without significant disruption.

- Anticipating technological advancements to ensure compatibility with future equipment.

2.2 Spares and Redundancy

Redundancy ensures system reliability by minimizing downtime in case of equipment failure.

The HVAC engineer should:

- Evaluate the need for standby equipment and spares.

- Design layouts to accommodate redundant units without compromising space efficiency.

- Prioritize ease of access to redundant systems for rapid deployment.

2.3 Adequate Space for Installation and Maintenance

Sufficient space is vital for:

- Installation of large HVAC components such as chillers, boilers, air handling units, and pumps.

- Performing routine maintenance, servicing, and eventual replacement of parts.

- Ensuring unrestricted access for technicians and material handling equipment.

- Compliance with safety regulations, which often mandate minimum clearance around equipment.

2.4 Walkways and Emergency Escape Paths

The design of walkways and emergency escape paths must adhere to safety codes and standards. Key considerations include:

- Primary and secondary escape routes with appropriate widths.

- Routing escape paths through the plant room to designated exits.

- Coordination with the health, safety, and environment (HSE) team to finalize escape path layouts.

- Ensuring HVAC equipment placement does not obstruct these pathways.

2.5 Material Handling

Throughout the life cycle of the HVAC system, maintenance activities (such as preventive and predictive maintenance) of equipment/components installed inside the HVAC plant room may require the repair or replacement of components or entire equipment.

To facilitate the removal of affected equipment/components and the installation of new ones, appropriate material handling equipment (like forklifts, trolleys, etc.,) will be necessary. Appropriate floor space and room height for material handling equipment movement shall be planned in the design.

Additionally, permanent arrangements (e.g., lifting beams, beam clamps, pad eyes, chain blocks, monorail, etc.) should be installed to support efficient and safe handling during such operations. Space required for these items handling shall be planned.

2.6 Doors and Access Points

Strategic placement of doors and access point facilitates:

- Safe and efficient movement of personnel and equipment.

- Compliance with fire safety regulations.

- Easy ingress and egress for maintenance activities.

- Accommodation of large equipment dimensions, necessitating wider or taller doorways. Normally AHU/FAHU cooling coil requires bigger room door for removing the cooling coil out of the room.

2.7. Acoustic Requirements

Noise control is a critical aspect of plant room design.

Measures include:

- Installing acoustic insulation or soundproofing materials to limit noise levels.

- Isolating vibration-prone equipment to reduce noise transmission.

- Designing layouts to minimize noise pollution in adjacent areas.

2.8 Coordination with Structural Engineer for Columns and Beams

Structural considerations greatly influence the HVAC plant room layout. Close collaboration with the structural engineer ensures:

- Proper placement of structural columns and beams to avoid interference with equipment.

- Adequate height clearance for ductwork, pipework, and auxiliary systems.

- Safe load-bearing capacity to support the weight of HVAC equipment.

- Flexibility to modify equipment layouts as structural details evolve.

2.9. Room Shape

A rectangular or square layout is preferred for HVAC plant rooms due to its:

- Space efficiency, allowing for better equipment organization.

- Simplified routing of ductwork and piping systems.

- Enhanced accessibility for maintenance and operations.

10. Weight Considerations

HVAC equipment can impose significant loads on the plant room structure. To address this:

- Provide detailed equipment weight data, including operational and static loads, to the structural engineer.

- Ensure structural integrity through reinforced floors and load-bearing walls.

2.11 Location

The location of the HVAC plant room impacts system performance and operational efficiency. Factors to consider include:

- Proximity to the areas being served to minimize ductwork length and reduce static pressure loss.

- Ease of drainage for condensate and other waste liquids.

- Accessibility for maintenance personnel and regulatory authorities.

- Optimal placement of intake and exhaust ducts to enhance ventilation efficiency.

2.12 Supporting Auxiliary Systems

In addition to HVAC equipment, plant rooms house several auxiliary systems, such as:

- Electrical trays and wiring.

- Firefighting piping and systems.

- Instrumentation trays and utility piping.

- Drainage systems.

Coordination among disciplines is critical to ensure:

- Efficient use of space while avoiding clashes between systems.

- Adequate height clearance at crossing points.

- Compliance with safety and operational standards.

3. Final Thoughts

The design of HVAC plant rooms is a critical aspect of any large-scale project, serving as the operational hub for heating, ventilation, and air conditioning systems. Proper planning and execution ensure operational efficiency, safety, and adaptability for future needs. By addressing key considerations such as space allocation, redundancy, accessibility, safety compliance, noise control, and structural integration, HVAC engineers can create functional and sustainable plant room designs. Effective collaboration among various disciplines—structural, civil, mechanical, electrical, and HSE teams—is essential to ensure a cohesive and optimized design. Ultimately, a well-designed HVAC plant room not only supports current operations but also provides flexibility to meet future technological and operational demands

4. References

- ASHRAE Handbook—Fundamentals

- ASHRAE Handbook—HVAC Systems and Equipment

5. Abbreviations

| AHU | Air Handling Unit |

| ASHRAE | American Society of Heating, Refrigerating, and Air-Conditioning Engineers |

| FAHU | Fresh Air Handling Unit |

| HVAC | Heating, Ventilation, and Air Conditioning |