1. Introduction

In comfort air conditioning, the main function of an HVAC system is to maintain and control the temperature, humidity, air cleanliness, and noise for varying ambient air conditions.

In cold climatic regions, during extreme winter conditions, the water content (in vapour form) in the atmospheric air will be too low. The water content is defined by the term specific humidity (kg of water vapor/kg of moist air).

In human comfort as well as in certain industrial applications (to minimize static electricity issues), in addition to minimum room temperature the minimum RH value should be maintained.

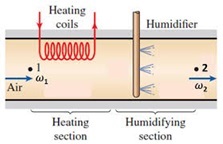

2. Humidification and Heating

To meet the minimum RH requirement, humidification, which involves adding water vapor (steam) to the supply air, is often necessary. This is achieved using a humidifier, a device typically installed within the Air Handling Unit (AHU) or in the supply ductwork.

To meet the room design temperature condition, based on the AHU’s type (100% fresh air or recirculation type), temperature condition of fresh air, return air, and airflow rates (of fresh air, return air), heating of the fresh air/or supply air may be required. The heating is normally done by an electric heater or by sensible heating using hot water piping system or by sensible heating using steam piping system

3. Heater and Humidifier position

For winter operation, based on the mixed air condition (in recirculation type AHU) or outdoor air temperature (100% fresh air AHU), to get the required space temperature & RH value, the position of the humidifier with respect to the electric heater is important otherwise the required room RH cannot be archived.

4. Case Study

Winter – Room Design Conditions

Let’s consider the following initial state point conditions on the standard psychrometric chart (At sea level).

- State Point “R”: Desired indoor conditions (20°C, 35% RH). It is the final point in the process.

- State Point “1”: Mixed air condition (for recirculation type AHU) or outdoor air temperature (for 100% fresh air AHU). Consider the standpoint condition of Minus 2 OC, 50% RH). It is the initial point in the process

For simplicity, we assume no latent load in the room and only sensible heat loss.

As we know to maintain a certain room temperature in the winter, the supply air temperature should be higher than the room air temperature.

Design Concept

The required final room condition is achieved by doing the following process on the mixed air (at State Point 1):

- Humidifying the air till it reaches the specific humidity same as of required design room air specific humidity

- Heating the mixed air condition to the temperature above the design room temperature

Now the question arises, which process to be started first?. Heating first and then humidification or Humidification first and then heating?.

We will solve this question in the below sections.

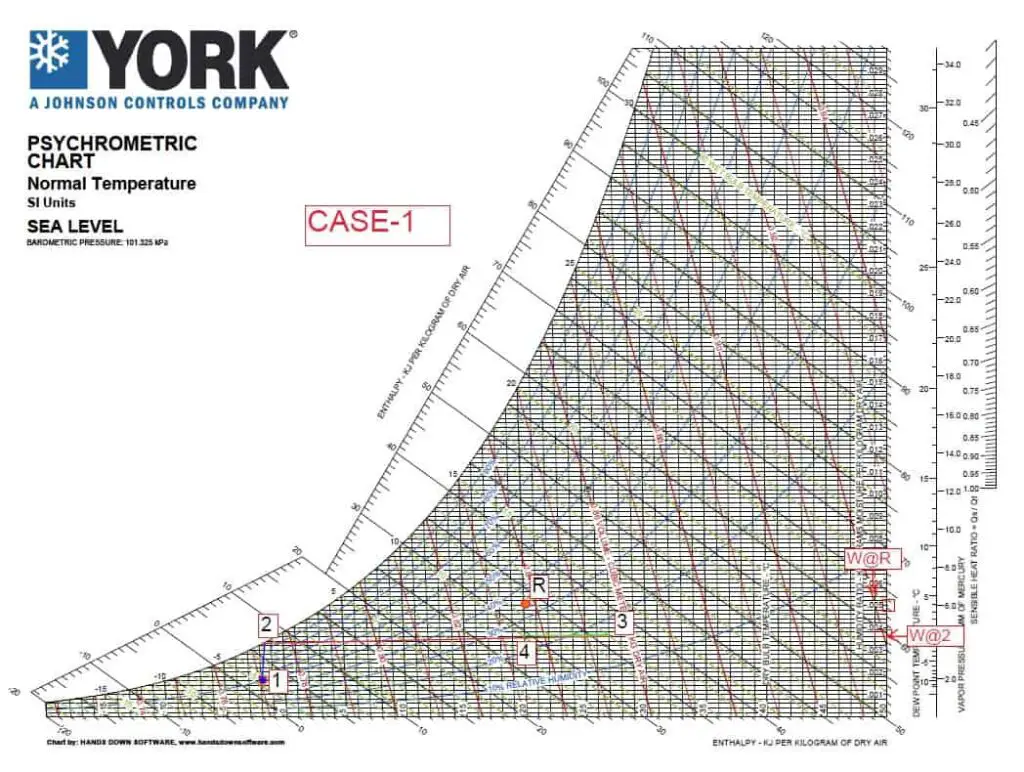

CASE 1: Humidifier Upstream of Electric Heater

In this case, along the flow direction, the humidifier is placed first, and then the electric heater. So, the humidification process will happen first and then heating.

In this configuration:

- Line 1-2: Represents the humidification process.

- Line 2-3: Represents the heating process.

- Line 3-4: Represents the room heating process.

Outcome:

From the below picture, we can understand that room design temperature can be achieved. However, we cannot achieve the design RH of 35%. This is due to the reason that at state point “2” the air is fully saturated and further adding water vapor (steam) is not possible. The humidity value corresponding to statepoint-2 (about 0.0037 kg of water vapor/kg of dry air) is much lower than the design humidity value (about 0.005 kg of water vapor/kg of dry air).

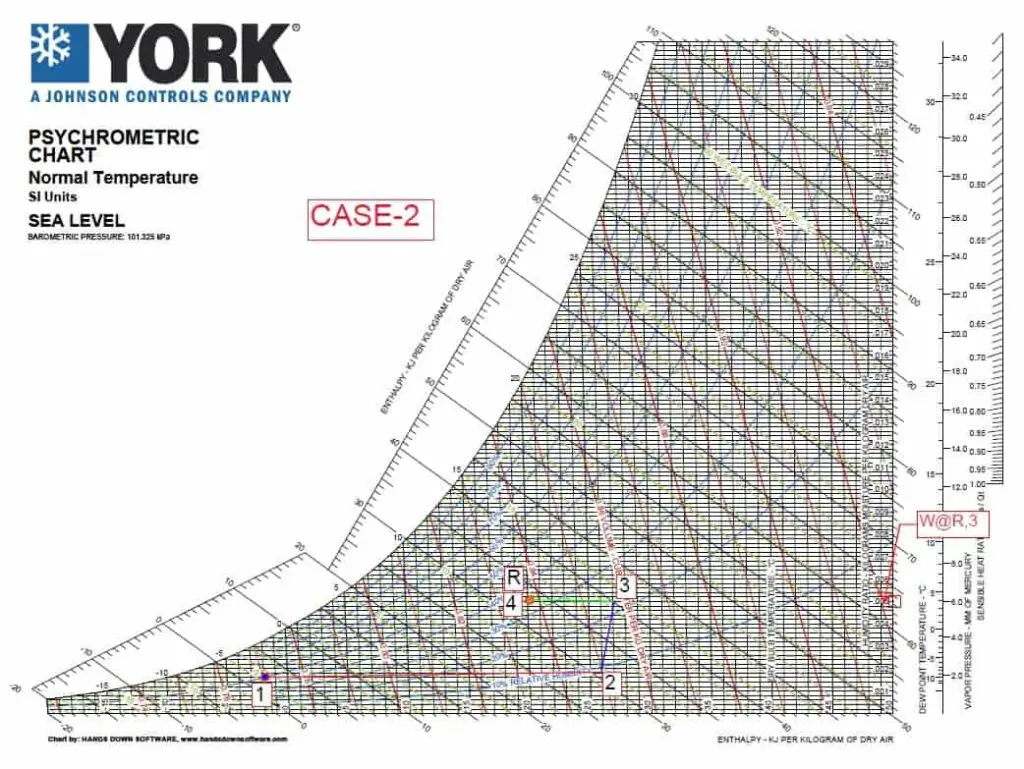

CASE 2: Humidifier Downstream of Electric Heater

In this case, along the flow direction, the electric heater is placed first, and then the humidifier. So, the heating process will happen first and then humidification.

In this configuration:

- Line 1-2: Represents the heating process.

- Line 2-3: Represents the humidification process.

- Line 3-4: Represents the room heating process.

Outcome:

Both the desired temperature and RH can be achieved. By heating the air first, its capacity to hold moisture increases, allowing the humidifier to add sufficient water vapor to meet the design conditions.

5. Conclusion

- Humidifier Placement Matters: Installing the humidifier downstream of the electric heater ensures the air can hold sufficient moisture, enabling the system to achieve the target RH.

- Psychrometric Analysis is Essential: Understanding the state points and transitions on the psychrometric chart is crucial for effective system design.

- System Configuration Impacts Performance: Consideration of AHU configuration, airflow rates, and temperature conditions helps optimize the placement of humidification and heating components.

Proper design and placement of the humidifier and heater in an HVAC system play a vital role in maintaining indoor comfort during extreme winter conditions, ensuring both temperature and RH targets are met efficiently.

6. References

- ASHRAE Handbook – Fundamental, Chapter “Nonresidential Cooling and Heating Load Calculations”

- ASHRAE Handbook – Applications, Chapter “Industrial Air Conditioning”

- ASHRAE Standard 55 – Thermal Environmental Conditions for Human Occupancy

- York Psychrometric Chart

7. Abbreviations

| AHU | Air Handling Unit |

| ASHRAE | American Society of Heating, Refrigerating, and Air-Conditioning Engineers |

| DBT | Dry Bulb Temperature |

| FAHU | Fresh Air Handling Unit |

| HVAC | Heating, Ventilation, and Air Conditioning |

| RH | Relative Humidity |